Description

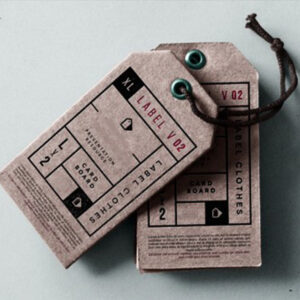

Material:

1. Natural Kraft Board

Natural Cardboard offers an ideal canvas for an organic aesthetic.

Crafted from 80% virgin wood fiber, it boasts the benefits of being

both 100% recyclable and biodegradable. With its organic texture

and availability in various flute types, Natural Cardboard perfectly

combines sustainability with style.

2. Oyster White Board

Oyster White Board, also known as Mottled White Board, is a

clay-coated CCNB linerboard featuring an elegant off-white

surface with subtle natural kraft undertones, making it ideal for

moderate-quality printing. This material is often selected for its

affordability as the most economical white corrugated option

available. Additionally, it boasts a high recycled content,

appealing to environmentally-conscious consumers. For those

seeking exceptional color vibrancy in their prints, Bleached White

or Kemi are recommended as superior alternatives.

3. Kemi White Board

Kemi White Board boasts a premium semi-gloss-coated brilliant

white C1S linerboard on one side, making it ideal for high-quality

printing and finishing. Its pre-applied semi-gloss coating ensures

that your prints achieve a stunning finish without the need for

additional coatings. The vibrant surface enhances the richness of

printed colors, delivering impressive results. However, it’s

important to note that Kemi White Board comes at a higher price

point compared to its mottled white counterpart.

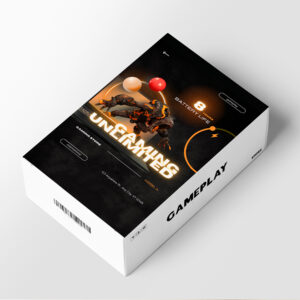

4. Bleached White Board

Bleached White Board boasts a stunning bleached kraft

linerboard on both sides, offering exceptional quality for printing

and finishing. Renowned for its brilliance, this premium material is

the brightest white corrugated board on the market, enhancing the

vibrancy of printed colors and making them pop like never before.

Its striking white surface not only elevates the visual appeal but

also positions it as the top-tier choice for those seeking the best in

corrugated materials.